Page 26 - NSK_CAT_E1102m_A7-141

P. 26

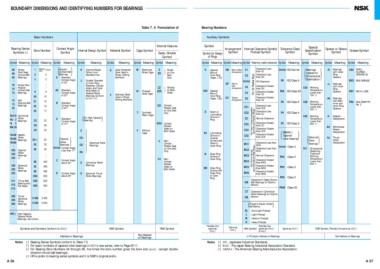

BOUNDARY DIMENSIONS AND IDENTIFYING NUMBERS FOR BEARINGS

Table 7. 6 Formulation of Bearing Numbers

Basic Numbers Auxiliary Symbols

Bearing Series Bore Number Contact Angle Internal Design Symbol Material Symbol Cage Symbol External Features Symbol Internal Clearance Symbol Tolerance Class Special Spacer or Sleeve Grease Symbol

Symbols (1) Symbol Arrangement Preload Symbol Symbol Specification Symbol

Seals, Shields

Symbol Symbol for Design Symbol Symbol

of Rings

Symbol Meaning Symbol Meaning Symbol Meaning Symbol Meaning Symbol Meaning Symbol Meaning Symbol Meaning Symbol Meaning Symbol Meaning Symbol Meaning (radial clearance) Symbol Meaning Symbol Meaning Symbol Meaning Symbol Meaning

68 Single- 1 Bearing 1mm ( )Angular A Internal Design g Case-Hardened M Machined }Z Shield K Tapered DB Back-to-Back C1 Clearance Less Omitted ISO Normal ( )Bearings +K Bearings AS2 SHELL

Row Deep Bore Differs from Steel Used in Brass Cage Bore of than C2 P6 ISO Class 6 treated for with Outer ALVANIA

Groove Ball Contact Ball Standard One Rings, Rolling on One Inner Ring Arrangement Clearance Less Dimensional Ring GREASE S2

69 22 Bearings Elements ZS Side (Taper 1:12) For All Radial Brgs. than CN Stabilization Spacers

A Standard J Smaller Diameter C2 ENS ENS GREASE

60 Bearings of Outer Ring h Stainless Steel Only K30 Tapered CN Clearance +L Bearings

33 Contact Angle Raceway, Contact Used in Rings, Bore of with Inner NS7 NS HI-LUBE

: ⋅⋅⋅⋅⋅⋅ ⋅⋅⋅⋅⋅⋅ of 30° Angle, and Outer Rolling Elements Inner Ring Omitted Clearance Greater Ring

99 Ring Width of (Taper 1:30) than CN Spacers PS2 MULTEMP PS

70 Single-Row A5 Standard Tapered Roller DF Face-to- Clearance Greater No. 2

Contact Angle Bearings Conform E Notch or Face than C3 +KL Bearings

72 Angular of 25° to ISO 355 }ZZ Shields Lubricating Arrangement C3 Clearance Greater X26 Working with Both

Contact Ball Groove in than C4 Inner and

B Standard ( )For High Capacity W Pressed ZZS on Both Ring P6X ISO Class 6X Temperature Outer Ring

73 Bearings Contact Angle Bearings Steel Cage Sides C4 Clearance Less Lower than Spacers

of 40° E4 Lubricating than CC2

: 00 100 C Groove in Clearance Less 150 °C H Adapter

C Standard Outside than CC Designation

12 Self- Contact Angle CA Surface and DT Tandem C5

13 Aligning Ball of 15° Spherical Roller Holes in Arrangement Normal Clearance AH Withdrawal

22 Bearings 01 120 Outer Ring P5 ISO Class 5 X28 Working Sleeve

02 150 ( )Tapered CD Bearings DU Contact CC1 Clearance Greater P4 ISO Class 4 Temperature Designation

170 EA Rubber Seal N Snap Ring CC2 than CC P2 ISO Class 2 Lower than

Roller Groove in CC For Non-Interchangeable 200 °C HJ Thrust

: 03 Bearings E Cylindrical Roller T Synthetic on One Side Outer Ring CC3 Cylindrical Roller Brgs. Collar

Omitted Contact Angle Bearings X29 Working Designation

Less than 17° Resin Cage Only NR Snap Ring Temperature

E Spherical Thrust Groove with Lower than

NU10 Cylindrical C Contact Angle Roller Bearings Snap Ring 250 °C

Roller about 20° in Outer

NJ 2 Bearings /22 220 Ring

/28 280 D Contact Angle

N3 /32 320 about 28° DDU Contact

Rubber

NN 30 Seals on Clearance Greater

Both Sides than CC3

: V Without CC4

Cage ( ) ( )CC5

NA48 Needle Clearance Greater ABMA(7)

Roller than CC4 Tapered Spherical

NA49 Bearings roller bearing Roller

04(3) 200 V Non-

Contact

NA69 05 250 Rubber Seal MC1 For Extra-Small Clearance Less than Omitted Class 4 Bearings

: on One Side MC2 and Miniature Ball Brgs. MC2

Only S11 Dimensional

320 Tapered 06 300 Clearance Less than Stabilizing

Roller MC3

Bearings ⋅⋅⋅⋅⋅⋅ ⋅⋅⋅⋅⋅⋅

322 MC3 Normal Clearance PN2 Class 2 Treatment

Working

323 (2) VV Non- Clearance Greater Temperature

Contact than MC3 Lower than

: 88 4400 Rubber MC4 200°C

Seals on

230 Spherical 92 4600 Both Sides MC5 Clearance Greater PN3 Class 3

Roller 96 4800 than MC4

222 Bearings

Clearance Greater

223 MC6 than MC5

: /500 5000 PN0 Class 0

Clearance in Deep Groove

511 Thrust Ball /530 5300 CM Ball Bearings for Electric

Bearing with 5600 Motors

512 Flat Seats /560

⋅⋅⋅⋅⋅ PN00 Class 00

513 ⋅⋅⋅⋅⋅ 2 360 00

: 2 500 00 CT Clearance in Cylindrical

Roller Bearings for Electric

292 Thrust /2 360

Spherical /2 500 CM Motors

Roller

293

294 Bearings ( )Preload of Angular Contact

Ball Bearing

:

EL Extra light Preload

HR(4) High Capacity

Tapered Roller L Light Preload

Bearings, and others M Medium Preload

Symbols and Numbers Conform to JIS(5) NSK Symbol NSK Symbol Partially the Same as H Heavy Preload Same as JIS(5) NSK Symbol, Partially the same as JIS(5)

same as JIS(5) Not Marked on Bearings

JIS(5) Partially the

NSK Symbol same as JIS(5)/

BAS(6)

Marked on Bearings Not Marked In Principle, Marked on Bearings

on Bearings

Notes (1) Bearing Series Symbols conform to Table 7.5. Notes (5) JIS : Japanese Industrial Standards.

A 56 (2) For basic numbers of tapered roller bearings in ISO's new series, refer to Page B111. (6) BAS : The Japan Bearing Industrial Association Standard.

(3) For Bearing Bore Numbers 04 through 96, five times the bore number gives the bore size (mm) (except double- (7) ABMA : The American Bearing Manufacturers Association.

direction thrust ball bearings).

(4) HR is prefix to bearing series symbols and it is NSK's original prefix.

A 57