Page 6 - e3317

P. 6

NSK Grease Clean

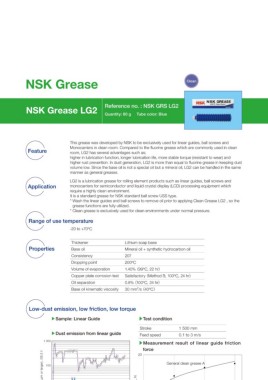

NSK Grease LG2 Reference no. : NSK GRS LG2

Quantity: 80 g Tube color: Blue

Feature This grease was developed by NSK to be exclusively used for linear guides, ball screws and

Application Monocarriers in clean room. Compared to the fluorine grease which are commonly used in clean

room, LG2 has several advantages such as;

higher in lubrication function, longer lubrication life, more stable torque (resistant to wear) and

higher rust prevention. In dust generation, LG2 is more than equal to fluorine grease in keeping dust

volume low. Since the base oil is not a special oil but a mineral oil, LG2 can be handled in the same

manner as general greases.

LG2 is a lubrication grease for rolling element products such as linear guides, ball screws and

monocarriers for semiconductor and liquid crystal display (LCD) processing equipment which

require a highly clean environment.

It is a standard grease for NSK standard ball screw USS type.

* Wash the linear guides and ball screws to remove oil prior to applying Clean Grease LG2 , so the

grease functions are fully utilized.

* Clean grease is exclusively used for clean environments under normal pressure.

Range of use temperature

-20 to +70ºC

Properties Thickener Lithium soap base

Base oil Mineral oil + synthetic hydrocarbon oil

Consistency 207

Dropping point 200ºC

Volume of evaporation 1.40% 99ºC, 22 hr

Copper plate corrosion test Satisfactory Method B, 100ºC, 24 hr

Oil separation 0.8% 100ºC, 24 hr

Base oil kinematic viscosity 30 mm2/s 40ºC

Low-dust emission, low friction, low torque

Sample: Linear Guide Test condition

Dust emission from linear guide Stroke 1 500 mm

Feed speed 0.1 to 3 m/s

1 000

Measurement result of linear guide friction

μm or larger), /28.3 ℓ

,N force

20

100 General clean grease A