Page 67 - NSK_CAT_E1102m_A7-141

P. 67

TECHNICAL DATA

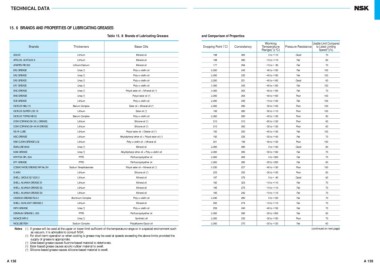

15. 6 BRANDS AND PROPERTIES OF LUBRICATING GREASES and Comparison of Properties

Table 15. 8 Brands of Lubricating Greases

Brands Thickeners Base Oils Dropping Point (˚C) Consistency Working Usable Limit Compared

Temperature Pressure Resistance to Listed Limiting

Range(1)(°C)

Speed(2)(%)

0 to +110

ADLEX Lithium Mineral oil 198 300 −10 to +110 Good 70

198 280 −10 to + 80

APOLOIL AUTOLEX A Lithium Mineral oil 177 294 −40 to +150 Fair 60

≥260 243 −40 to +150

ARAPEN RB 300 Lithium/Calcium Mineral oil ≥260 230 −40 to +160 Fair 70

≥260 251 −40 to +160

EA2 GREASE Urea (3) Poly-α-olefin oil ≥260 243 −40 to +160 Fair 100

≥260 262 −40 to +160

EA3 GREASE Urea (3) Poly-α-olefin oil ≥260 264 −10 to +120 Fair 100

≥260 235 −30 to +120

EA5 GREASE Urea (3) Poly-α-olefin oil ≥260 280 −50 to +110 Good 60

195 280 −40 to +130

EA7 GREASE Urea (3) Poly-α-olefin oil ≥260 280 −60 to +120 Fair 100

210 310 −30 to +130

ENC GREASE Urea (3) Polyol ester oil + Mineral oil (4) 210 260 −40 to +130 Fair 70

192 250 −30 to +140

ENS GREASE Urea (3) Polyol ester oil (4) 192 235 −40 to +130 Poor 100

201 199

ECE GREASE Lithium Poly-α-olefin oil ≥260 280 0 to +130 Fair 100

≥260 283 −30 to +160

ISOFLEX NBU 15 Barium Complex Ester oil + Mineral oil (4) ≥260 265 Poor 100

≥260 280 0 to +200

ISOFLEX SUPER LDS 18 Lithium Ester oil (4) ≥230 227 −30 to +200 Poor 100

223 252 −40 to +130

ISOFLEX TOPAS NB 52 Barium Complex Poly-α-olefin oil 187 276 −30 to +130 Poor 90

182 323

DOW CORNING SH 33 L GREASE Lithium Silicone oil (5) 185 275 0 to + 80 Poor 60

185 242 −10 to +110

DOW CORNING SH 44 M GREASE Lithium Silicone oil (5) ≥240 280 −10 to +110 Poor 60

200 274 −10 to +110

NS HI-LUBE Lithium Polyol ester oil + Diester oil (4) 259 240 Fair 100

≥260 280 0 to +120

NSC GREASE Lithium Alkyldiphenyl ether oil + Polyol ester oil (4) ≥260 230 −10 to +110 Fair 70

≥260 270 −40 to +150

NSK CLEAN GREASE LG2 Lithium Poly-α-olefin oil + Mineral oil −30 to +200 Poor 100

−30 to +150

EMALUBE 8030 Urea (3) Mineral oil −20 to +120 Good 60

MA8 GREASE Urea (3) Alkyldiphenyl ether oil + Poly-α-olefin oil Fair 70

KRYTOX GPL-524 PTFE Perfluoropolyether oil Fair 70

KP1 GREASE PTFE Perfluoropolyether oil Fair 60

COSMO WIDE GREASE WR No.3N Sodium Terephtalamate Polyol ester oil + Mineral oil (4) Poor 100

G-40M Lithium Silicone oil (5) Poor 60

SHELL GADUS S2 V220 2 Lithium Mineral oil Good 60

SHELL ALVANIA GREASE S1 Lithium Mineral oil Fair 70

SHELL ALVANIA GREASE S2 Lithium Mineral oil Fair 70

SHELL ALVANIA GREASE S3 Lithium Mineral oil Fair 70

CASSIDA GREASE RLS 2 Aluminum Complex Poly-α-olefin oil Fair 70

SHELL SUNLIGHT GREASE 2 Lithium Mineral oil Fair 70

WPH GREASE Urea (3) Poly-α-olefin oil Fair 70

DEMNUM GREASE L-200 PTFE Perfluoropolyether oil Fair 60

NIGACE WR-S Urea (3) Synthetic oil Poor 70

NIGLUBE RSH Sodium Complex Polyalkylene Glycol oil Fair 60

Notes (1) If grease will be used at the upper or lower limit sufficient of the temperature range or in a special environment such (continued on next page)

as vacuum, it is advisable to consult NSK.

Notes

(2) For short-term operation or when cooling is grease may be used at speeds exceeding the above limits provided the

Notes supply of grease is appropriate.

Notes

Notes (3) Urea-based grease causes fluorine-based material to deteriorate.

(4) Ester-based grease causes acrylic rubber material to swell.

(5) Silicone-based grease causes silicone-based material to swell.

A 138 A 139