Page 3 - NSK_CAT_E1102m_A7-141

P. 3

TYPES AND FEATURES OF ROLLING BEARINGS

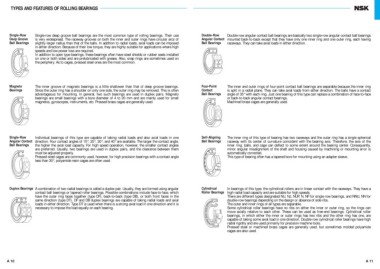

Single-Row Single-row deep groove ball bearings are the most common type of rolling bearings. Their use Double-Row Double-row angular contact ball bearings are basically two single-row angular contact ball bearings

Deep Groove is very widespread. The raceway grooves on both the inner and outer rings have circular arcs of Angular Contact mounted back-to-back except that they have only one inner ring and one outer ring, each having

Ball Bearings slightly larger radius than that of the balls. In addition to radial loads, axial loads can be imposed Ball Bearings raceways. They can take axial loads in either direction.

in either direction. Because of their low torque, they are highly suitable for applications where high

speeds and low power loss are required.

In addition to open type bearings, these bearings often have steel shields or rubber seals installed

on one or both sides and are prelubricated with grease. Also, snap rings are sometimes used on

the periphery. As to cages, pressed steel ones are the most common.

Magneto The inner groove of magneto bearings is a little shallower than that of deep groove bearings. Four-Point The inner and outer rings of four-point contact ball bearings are separable because the inner ring

Bearings Since the outer ring has a shoulder on only one side, the outer ring may be removed. This is often Contact is split in a radial plane. They can take axial loads from either direction. The balls have a contact

advantageous for mounting. In general, two such bearings are used in duplex pairs. Magneto Ball Bearings angle of 35° with each ring. Just one bearing of this type can replace a combination of face-to-face

bearings are small bearings with a bore diameter of 4 to 20 mm and are mainly used for small or back-to-back angular contact bearings.

magnetos, gyroscopes, instruments, etc. Pressed brass cages are generally used. Machined brass cages are generally used.

Single-Row Individual bearings of this type are capable of taking radial loads and also axial loads in one Self-Aligning The inner ring of this type of bearing has two raceways and the outer ring has a single spherical

Angular Contact direction. Four contact angles of 15°, 25°, 30°, and 40° are available. The larger the contact angle, Ball Bearings raceway with its center of curvature coincident with the bearing axis. Therefore, the axis of the

Ball Bearings the higher the axial load capacity. For high speed operation, however, the smaller contact angles inner ring, balls, and cage can deflect to some extent around the bearing center. Consequently,

minor angular misalignment of the shaft and housing caused by machining or mounting error is

are preferred. Usually, two bearings are used in duplex pairs, and the clearance between them automatically corrected.

must be adjusted properly. This type of bearing often has a tapered bore for mounting using an adapter sleeve.

Pressed-steel cages are commonly used, however, for high precision bearings with a contact angle

less than 30°, polyamide resin cages are often used.

Duplex Bearings A combination of two radial bearings is called a duplex pair. Usually, they are formed using angular Cylindrical In bearings of this type, the cylindrical rollers are in linear contact with the raceways. They have a

contact ball bearings or tapered roller bearings. Possible combinations include face-to-face, which Roller Bearings high radial load capacity and are suitable for high speeds.

have the outer ring faces together (type DF), back-to-back (type DB), or both front faces in the There are different types designated NU, NJ, NUP, N, NF for single-row bearings, and NNU, NN for

same direction (type DT). DF and DB duplex bearings are capable of taking radial loads and axial double-row bearings depending on the design or absence of side ribs.

loads in either direction. Type DT is used when there is a strong axial load in one direction and it is The outer and inner rings of all types are separable.

necessary to impose the load equally on each bearing. Some cylindrical roller bearings have no ribs on either the inner or outer ring, so the rings can

move axially relative to each other. These can be used as free-end bearings. Cylindrical roller

bearings, in which either the inner or outer rings has two ribs and the other ring has one, are

capable of taking some axial load in one direction. Double-row cylindrical roller bearings have high

radial rigidity and are used primarily for precision machine tools.

Pressed steel or machined brass cages are generally used, but sometimes molded polyamide

cages are also used.

A 10 A 11