Page 4 - NSK_CAT_E1102m_A7-141

P. 4

TYPES AND FEATURES OF ROLLING BEARINGS

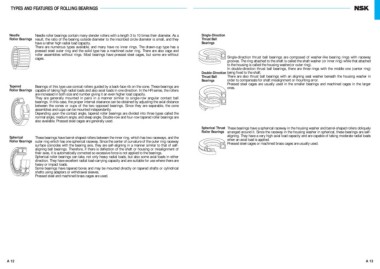

Needle Needle roller bearings contain many slender rollers with a length 3 to 10 times their diameter. As a Single-Direction

Roller Bearings result, the ratio of the bearing outside diameter to the inscribed circle diameter is small, and they Thrust Ball

have a rather high radial load capacity. Bearings

There are numerous types available, and many have no inner rings. The drawn-cup type has a

pressed steel outer ring and the solid type has a machined outer ring. There are also cage and Single-direction thrust ball bearings are composed of washer-like bearing rings with raceway

roller assemblies without rings. Most bearings have pressed steel cages, but some are without

cages. grooves. The ring attached to the shaft is called the shaft washer (or inner ring) while that attached

to the housing is called the housing washer(or outer ring).

In double-direction thrust ball bearings, there are three rings with the middle one (center ring)

Double-Direction being fixed to the shaft.

Thrust Ball There are also thrust ball bearings with an aligning seat washer beneath the housing washer in

Bearings order to compensate for shaft misalignment or mounting error.

Tapered Bearings of this type use conical rollers guided by a back-face rib on the cone. These bearings are Pressed steel cages are usually used in the smaller bearings and machined cages in the larger

Roller Bearings capable of taking high radial loads and also axial loads in one direction. In the HR series, the rollers

are increased in both size and number giving it an even higher load capacity. ones.

They are generally mounted in pairs in a manner similar to single-row angular contact ball

bearings. In this case, the proper internal clearance can be obtained by adjusting the axial distance

between the cones or cups of the two opposed bearings. Since they are separable, the cone

assemblies and cups can be mounted independently.

Depending upon the contact angle, tapered roller bearings are divided into three types called the

normal angle, medium angle, and steep angle. Double-row and four-row tapered roller bearings are

also available. Pressed steel cages are generally used.

Spherical These bearings have barrel-shaped rollers between the inner ring, which has two raceways, and the Spherical Thrust These bearings have a spherical raceway in the housing washer and barrel-shaped rollers obliquely

Roller Bearings outer ring which has one spherical raceway. Since the center of curvature of the outer ring raceway Roller Bearings arranged around it. Since the raceway in the housing washer in spherical, these bearings are self-

surface coincides with the bearing axis, they are self-aligning in a manner similar to that of self-

aligning ball bearings. Therefore, if there is deflection of the shaft or housing or misalignment of aligning. They have a very high axial load capacity and are capable of taking moderate radial loads

their axes, it is automatically corrected so excessive force is not applied to the bearings. when an axial load is applied.

Spherical roller bearings can take, not only heavy radial loads, but also some axial loads in either Pressed steel cages or machined brass cages are usually used.

direction. They have excellent radial load-carrying capacity and are suitable for use where there are

heavy or impact loads.

Some bearings have tapered bores and may be mounted directly on tapered shafts or cylindrical

shafts using adapters or withdrawal sleeves.

Pressed steel and machined brass cages are used.

A 12 A 13