Page 9 - NSK_CAT_E1102m_A7-141

P. 9

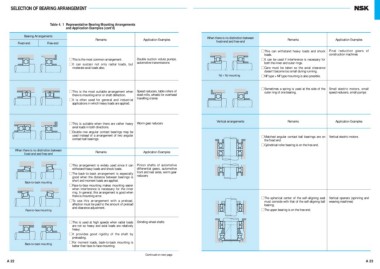

SELECTION OF BEARING ARRANGEMENT

Table 4. 1 Representative Bearing Mounting Arrangements

and Application Examples (cont'd)

Bearing Arrangements When there is no distinction between

fixed-end and free-end

Remarks Application Examples Remarks Application Examples

Fixed-end Free-end

fThis can withstand heavy loads and shock Final reduction gears of

loads. construction machines

fThis is the most common arrangement. Double suction volute pumps, fIt can be used if interference is necessary for

automotive transmissions both the inner and outer rings.

fIt can sustain not only radial loads, but

moderate axial loads also. fCare must be taken so the axial clearance

doesn't become too small during running.

NJ + NJ mounting

fNF type + NF type mounting is also possible.

fThis is the most suitable arrangement when Speed reducers, table rollers of fSometimes a spring is used at the side of the Small electric motors, small

there is mounting error or shaft deflection. steel mills, wheels for overhead

travelling cranes outer ring of one bearing. speed reducers, small pumps

fIt is often used for general and industrial

applications in which heavy loads are applied.

fThis is suitable when there are rather heavy Worm gear reducers Vertical arrangements Remarks Application Examples

axial loads in both directions.

fMatched angular contact ball bearings are on Vertical electric motors

fDouble row angular contact bearings may be the fixed end.

used instead of a arrangement of two angular

contact ball bearings. fCylindrical roller bearing is on the free end.

When there is no distinction between Remarks Application Examples

fixed-end and free-end

fThis arrangement is widely used since it can Pinion shafts of automotive

withstand heavy loads and shock loads. differential gears, automotive

front and rear axles, worm gear

fThe back-to-back arrangement is especially reducers

good when the distance between bearings is

Back-to-back mounting short and moment loads are applied. fThe spherical center of the self-aligning seat Vertical openers (spinning and

Face-to-face mounting must coincide with that of the self-aligning ball weaving machines)

fFace-to-face mounting makes mounting easier bearing.

when interference is necessary for the inner

ring. In general, this arrangement is good when fThe upper bearing is on the free end.

there is mounting error.

fTo use this arrangement with a preload,

affection must be paid to the amount of preload

and clearance adjustment.

fThis is used at high speeds when radial loads Grinding wheel shafts

are not so heavy and axial loads are relatively

Back-to-back mounting heavy.

A 22 fIt provides good rigidity of the shaft by

preloading.

fFor moment loads, back-to-back mounting is

better than face-to-face mounting.

Continued on next page

A 23