Page 11 - e3331

P. 11

5 Food Processing, Medical/Nursing Equipment

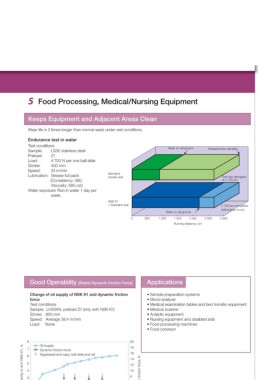

Keeps Equipment and Adjacent Areas Clean

Wear life is 3 times longer than normal seals under wet conditions.

Endurance test in water

Test conditions Wear on rail groove Rusted inside ball slide

Sample: LS30 stainless steel

Preload: Z1

Load: 4 700 N per one ball slide

Stroke: 400 mm

Speed: 24 m/min Standard

double seal

Lubrication: Grease full pack End cap damaged

NSK K1 at 2 700 km

(Consistency: 280, + Standard seal

Viscosity: 580 cst) 0

Water exposure: Run in water 1 day per

week.

Wear on rail groove 2 700 km completed

(still enable to run)

500 1 000 1 500 2 000 2 500 3 000

Running distance, km

Good Operability (Stable Dynamic friction Force) Applications

Change of oil supply of NSK K1 and dynamic friction • Sample preparation systems

force • Blood analyzer

Test conditions • Medical examination tables and bed transfer equipment

Sample: LH30AN, preload Z1 (only with NSK K1) • Medical scanner

Stroke: 800 mm • Analytic equipment

Speed: Average 38.4 m/min • Nursing equipment and disabled aids

Load: None • Food processing machines

• Food conveyor

8 20

Oil supply 18

16

7 Dynamic friction force 14

6 Degreased end caps, ball slide and rail 12

10

5 8

4

3

ntity of oil in NSK K1, %

friction force, N