Page 9 - e3331

P. 9

3 Woodworking Machines

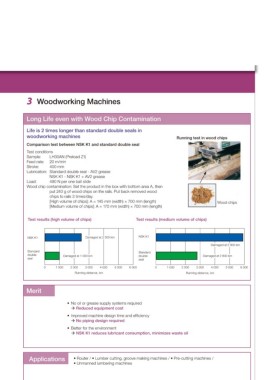

Long Life even with Wood Chip Contamination

Life is 2 times longer than standard double seals in Running test in wood chips

woodworking machines Wood chips

Comparison test between NSK K1 and standard double seal

Test conditions

Sample: LH30AN (Preload Z1)

Feed rate: 20 m/min

Stroke: 400 mm

Lubrication: Standard double seal - AV2 grease

NSK K1 - NSK K1 + AV2 grease

Load: 490 N per one ball slide

Wood chip contamination: Set the product in the box with bottom area A, then

put 240 g of wood chips on the rails. Put back removed wood

chips to rails 3 times/day.

[High volume of chips]: A = 145 mm (width) × 700 mm (length)

[Medium volume of chips]: A = 170 mm (width) × 700 mm (length)

Test results (high volume of chips) Test results (medium volume of chips)

NSK K1 Damaged at 2 500 km NSK K1

Standard Damaged at 5 900 km

double

seal Damaged at 1 000 km Standard Damaged at 2 800 km

double

0 seal

1 000 2 000 3 000 4 000 5 000 6 000 0 1 000 2 000 3 000 4 000 5 000 6 000

Running distance, km Running distance, km

Merit

• No oil or grease supply systems required

Reduced equipment cost

• Improved machine design time and efficiency

No piping design required

• Better for the environment

NSK K1 reduces lubricant consumption, minimizes waste oil

Applications • Router / • Lumber cutting, groove making machines / • Pre-cutting machines /

• Unmanned lumbering machines