Page 7 - e3331

P. 7

Introduction of Performance by Use

1 Automotive Manufacturing Equipment

Maintenance Free, Long Life even in Severe Environments

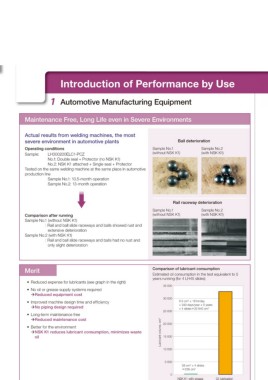

Actual results from welding machines, the most Ball deterioration

severe environment in automotive plants

Sample No.1 Sample No.2

Operating conditions (without NSK K1) (with NSK K1)

Sample: LH300200ELC1-PCZ

No.1: Double seal + Protector (no NSK K1)

No.2: NSK K1 attached + Single seal + Protector

Tested on the same welding machine at the same place in automotive

production line

Sample No.1: 10.5-month operation

Sample No.2: 13-month operation

Rail raceway deterioration

Comparison after running Sample No.1 Sample No.2

Sample No.1 (without NSK K1) (without NSK K1) (with NSK K1)

: Rail and ball slide raceways and balls showed rust and

extensive deterioration

Sample No.2 (with NSK K1)

: Rail and ball slide raceways and balls had no rust and

only slight deterioration

Merit Comparison of lubricant consumption

Estimated oil consumption in the test equivalent to 5

• Reduced expense for lubricants (see graph in the right) years running (for 4 LH45 slides)

• No oil or grease supply systems required 35 000

Reduced equipment cost

30 000 0.3 cm3 × 16 hr/day

• Improved machine design time and efficiency 25 000 × 340 days/year × 5 years

No piping design required × 4 slides 32 640 cm3

• Long-term maintenance free Lubricant volume, cm3 20 000

Reduced maintenance cost

15 000

• Better for the environment

NSK K1 reduces lubricant consumption, minimizes waste

oil

10 000

5 000 59 cm3 × 4 slides

0 236 cm3

NSK K1 with grease Oil lubrication